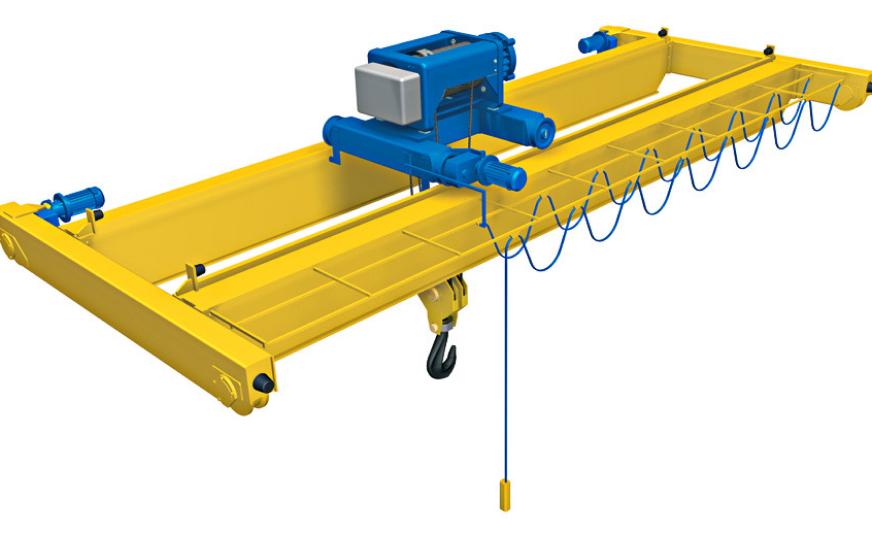

DOUBLE GIRDER EOT CRANE

S.K. Engineering's Double Girder EOT Cranes are rugged in Construction and are deployed for a wide range of hoisting capacities and applications. Our cranes combine high speed and high hooks for steel, metal and various other sectors which need heavy service.

With SWLs ranging from 3.2 to more than 500t, our cranes incorporate either standard ABUS crabs for up to 100t SWL or fully customised open winch type crabs. S.K. Engineering’s fully customised double girder cranes are suitable for varied duty cycles for a large range of spans, heights of lift and customizable speeds. They are provided with multiple hoisting trolleys running on the same bridge or auxiliary hoisting mechanisms on the main trolley. Precise control of all motions is achieved through variable frequency drives.

Specifications

| 1 | Capacity (t) | (3.2- 500) |

| 2 | Span (m) | (3-60) |

| 3 | Height of Lift (m) | (3-300) |

| 4 | Location | Indoor & Outdoor |

| 5 | Ambient Temperature (Degree Celsius) | Upto 50 |

| 6 | Crane Control | Pendant Radio Remote Control |

| 7 | Power Source | Shrouded DSL, MS Angle DSL, Drag Chain |

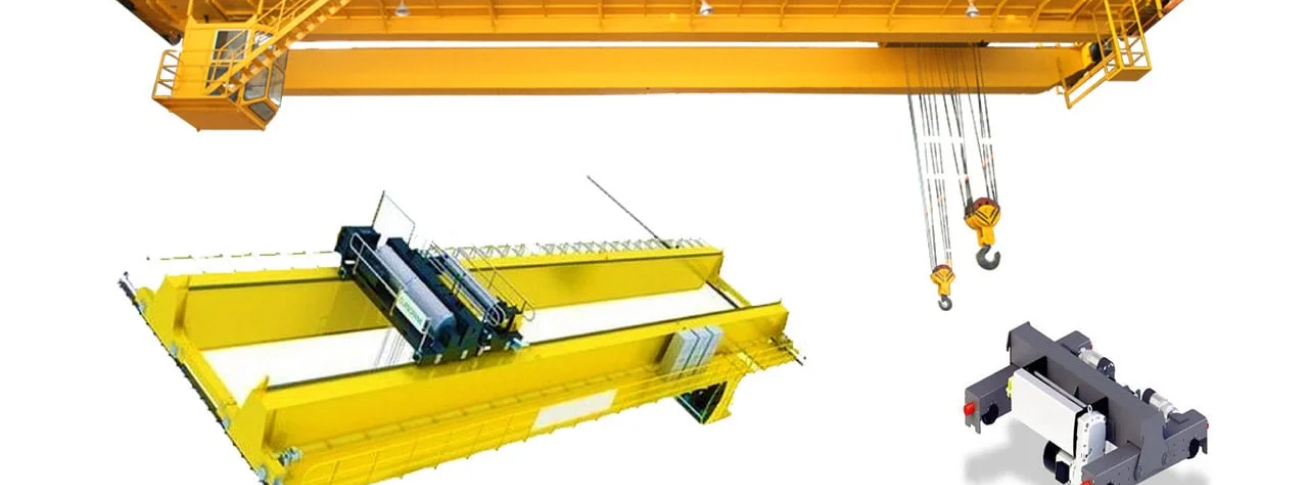

From our gallery

Service Feature Highlights

- Maintenance Platforms

- Limit Switches

- Under Bridge Lights

- Hooter + Flasher

- Crane Anti Collision

- Hardened & ground gear boxes

- Steel Core Wire Ropes

Some FAQ About This Product

A Double Girder Electric Overhead Traveling (EOT) Crane is a type of crane with two parallel girders supporting the bridge. It is designed for heavy-duty applications and offers higher load capacities compared to single girder cranes.

These cranes are designed for medium to heavy loads, ranging from 10 tons to 250 tons or more, depending on the design and customization.

Control options include cabin control for precise operations, pendant controls for ground-based handling, and wireless remote control for flexibility and ease of operation.

Safety features often include overload protection, limit switches to prevent excessive movement, anti-collision systems, emergency stop mechanisms, and advanced braking systems for precise control.

Regular maintenance includes inspecting structural components, testing electrical systems, lubricating moving parts, and replacing worn-out components to ensure safety and efficiency.