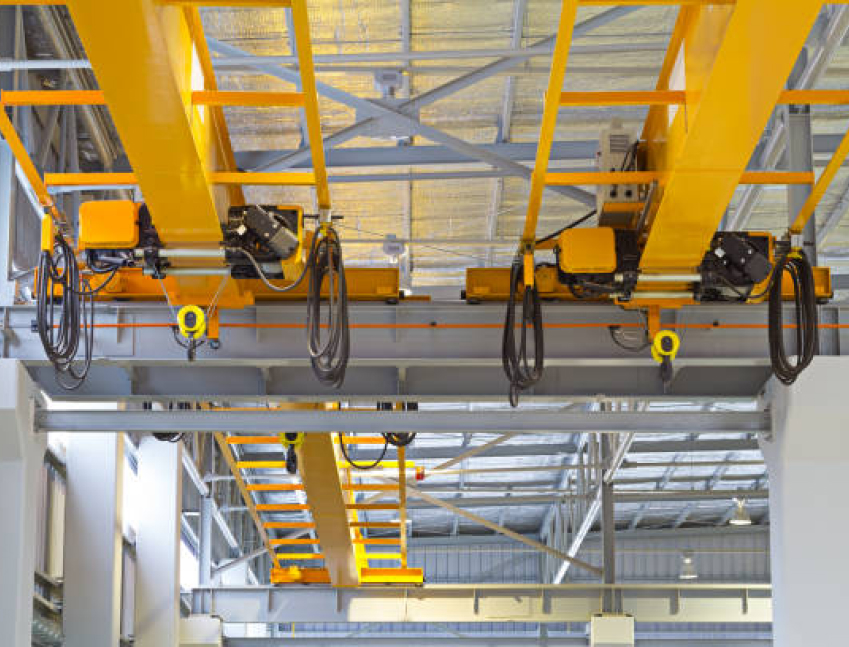

MS EOT CRANE

It is extensively used in warehouses and the industrial sector. This crane is able enough to carry heavy-duty objects for lifting purposes. MS EOT Crane is easy to use and required to lift heavier loads in comparison to manual hoists. It enables less space, shortened prep time, and easy material transport. It consists of parallel runways to give a flawless operation.

Product Details:

| Girder Type | Double |

| Brand | S.K. Engineering |

| Crane Type | Double Girder EOT Crane |

| Usage/Application | Industrial |

| Power Source | Electric |

| Load Capacity | 15 Ton |

| Span | 40 feet |

| Duty Class | Class II Duty |

| Power Supply | 3 Phase |

| Country of Origin | Made in India |

We are dedicatedly engaged in offering a qualitative range of EOT MS EOT cranes used to cater to the lifting and material handling purposes of various Industries. It is highly efficient in serving its purpose right & also made to fulfill all the ISO standards to provide its customers with an everlasting experience. Liftboy provides these overhead cranes at competitive rates within a stipulated time frame.

From our gallery

Service Feature Highlights

- Sturdy construction

- Efficient Operation

- Load Capacity

- Easy installation

- Ease of Maintenance

- Space-Efficient Design

- Energy Efficiency

Some FAQ About This Product

An MS EOT Crane is an overhead crane with a structure made from mild steel. It uses electric motors for the operation of its hoist and trolley. These cranes are designed for general material handling tasks in industries like manufacturing, warehouses, and construction.

MS EOT cranes typically come with load capacities ranging from 1 ton to 20 tons or more, depending on the application.

Yes, MS EOT cranes are highly customizable in terms of span, lifting height, capacity, and operational controls. They can be adapted for specific operational needs.

With proper maintenance, an MS EOT crane can last anywhere between 10 to 25 years, depending on the frequency of use, load handling, and maintenance practices.

The advantages include cost-effectiveness, easy maintenance, versatility in operation, and suitability for medium-duty applications.