EOT Cranes: A Comprehensive Guide to Electric Overhead Traveling Cranes

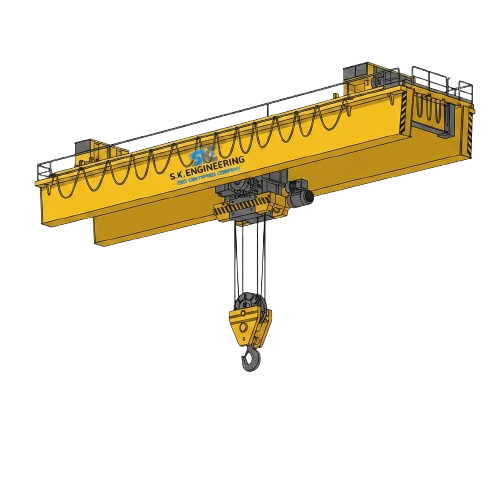

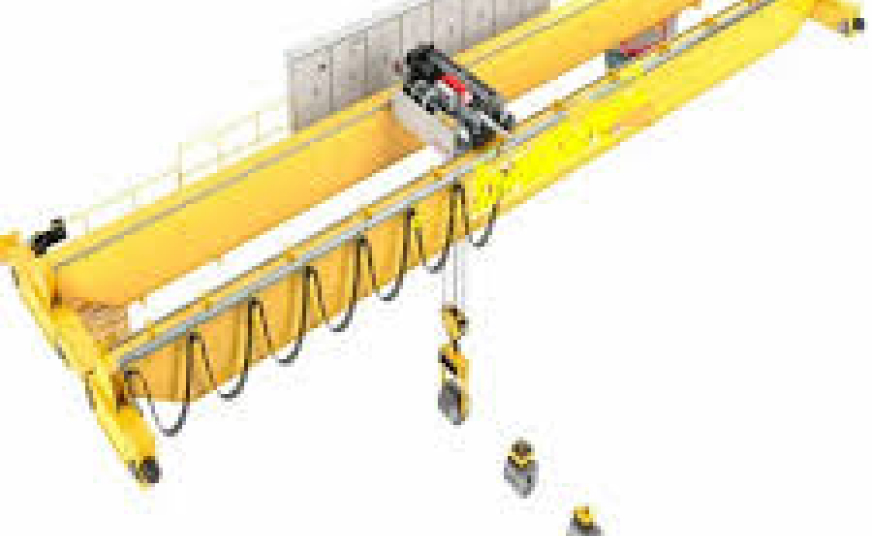

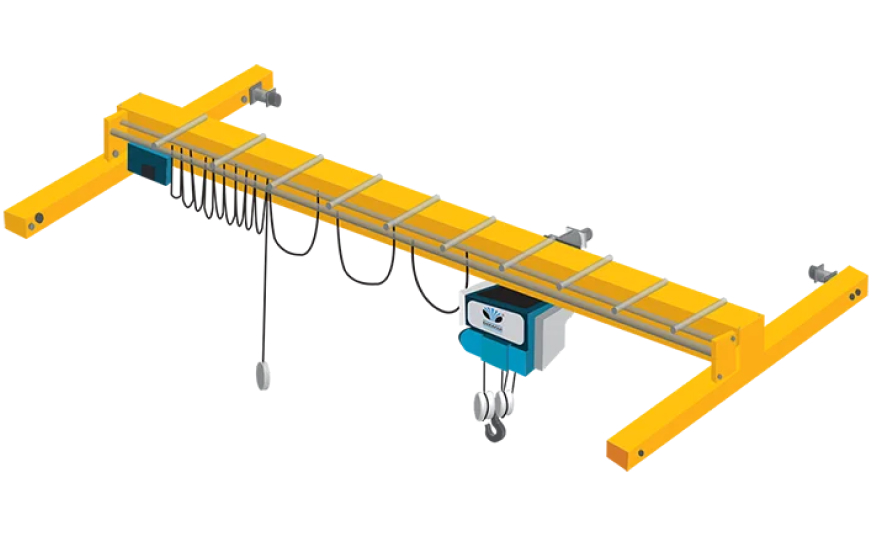

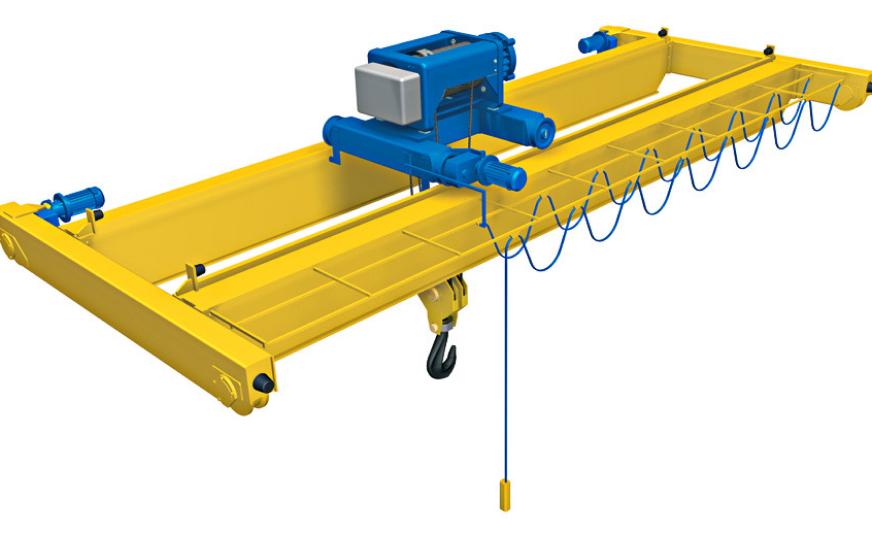

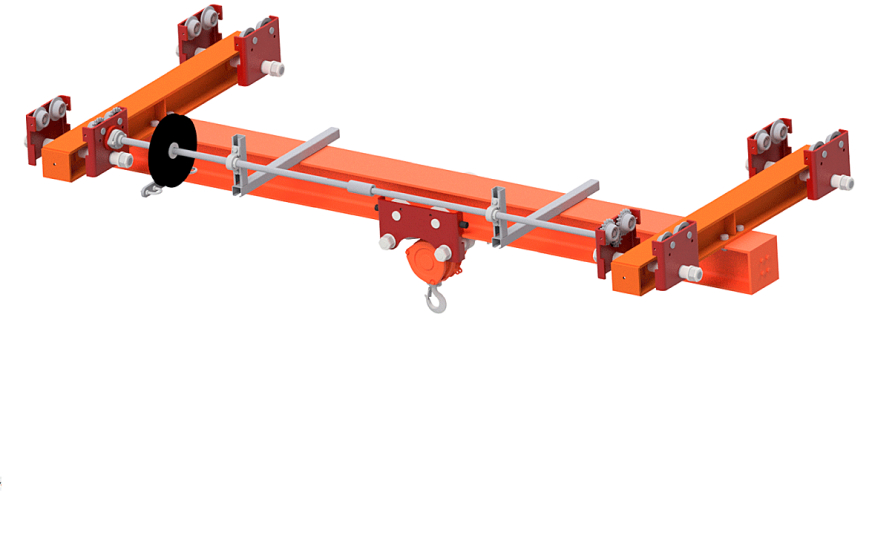

Electric Overhead Traveling (EOT) cranes are an integral part of modern material handling systems. These cranes are commonly used in manufacturing plants, warehouses, shipyards, and construction sites for lifting and transporting heavy loads across a predefined area. This blog will delve into the functionality, components, applications, and advantages of EOT cranes. What is an EOT Crane? An EOT crane, or Electric Overhead Traveling crane, is a type of crane that operates on overhead tracks and is powered by electricity. They are designed to lift and move heavy loads in a horizontal direction across a factory or warehouse. These cranes consist of two main components: a bridge and a hoist system. The bridge spans the length of the area, and the hoist system is responsible for lifting the load. Key Components of an EOT Crane An EOT crane is made up of several crucial components that work together to ensure smooth operation. Here are the main parts: Bridge: The horizontal structure that spans the workspace. It moves along the tracks, carrying the hoist. Hoist Mechanism: This is the part of the crane responsible for raising and lowering the load. It includes a motor, drum, and wire rope. End Trucks: These are mounted at both ends of the bridge and are responsible for the movement of the crane along the tracks. Electric Motor: Powers the crane's movements, including lifting, lowering, and horizontal movements. Control System: EOT cranes come with either a pendant control or a remote control system that allows the operator to control the crane from a distance. Tracks and Rail System: Tracks are laid out on the floor to support and guide the movement of the crane. How EOT Cranes Work The operation of an EOT crane involves a combination of horizontal and vertical motions. The crane's hoist system is used to raise and lower the load, while the bridge moves horizontally along the tracks. The movement of the crane can be controlled through a pendant or wireless remote control, giving operators the flexibility to position the load accurately and efficiently. The electric motor in the crane is powered by an external electrical supply, allowing the crane to operate smoothly without requiring manual effort or additional energy sources. Applications of EOT Cranes EOT cranes are widely used in various industries due to their versatility and heavy-duty capabilities. Some of the most common applications include: Manufacturing Plants: EOT cranes are used for moving heavy equipment, components, and materials from one part of the factory to another. Steel Mills and Foundries: They are essential in steel production facilities for moving heavy metal billets, sheets, and other materials. Warehouses and Distribution Centers: These cranes help in stacking and transporting goods quickly and efficiently. Construction Sites: EOT cranes assist in lifting construction materials, beams, and structural components. Shipyards: In shipbuilding, EOT cranes are used to transport heavy loads such as ship parts and engines. Advantages of EOT Cranes There are several benefits to using EOT cranes for material handling: Increased Productivity: EOT cranes significantly reduce the time required to move heavy loads, improving overall efficiency and productivity. Enhanced Safety: The crane reduces the risk of manual handling injuries, as the heavy lifting is done by the crane, not by workers. Energy Efficiency: Electric cranes consume less energy compared to manual or hydraulic cranes. Reduced Maintenance: EOT cranes require minimal maintenance when compared to other types of cranes, thanks to their advanced motorized systems and robust construction. Cost-effective: EOT cranes are a one-time investment that can result in lower operational costs over the long term. Maintenance and Care of EOT Cranes Regular maintenance is essential to ensure that an EOT crane continues to function effectively. Key maintenance activities include: Routine Inspections: Check for wear and tear on the hoist, motor, and tracks. Lubrication: Ensure that all moving parts are properly lubricated to avoid friction and wear. Electrical System Checks: Regularly inspect the electrical wiring and control systems to ensure proper functioning. Load Testing: Periodically test the crane's load capacity to ensure it can handle the required weights. Proper maintenance ensures that the crane operates at peak performance, minimizes downtime, and extends its service life. Conclusion EOT cranes play a vital role in modern industry, offering a reliable and efficient solution for lifting and moving heavy loads. With their robust design, powerful electric motors, and versatility, they help businesses optimize their material handling processes. Whether in manufacturing, construction, or shipbuilding, EOT cranes are essential for maintaining productivity and safety.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)